Community Updates

The Taylors Road Resource Recovery Precinct and EarthSure community updates page aims to help share an understanding of our operations by hosting informative resources and sharing planned and recent activities whilst providing a platform for Veolia and the local community to engage.

Community Updates will be updated periodically to best address current topics of interest.

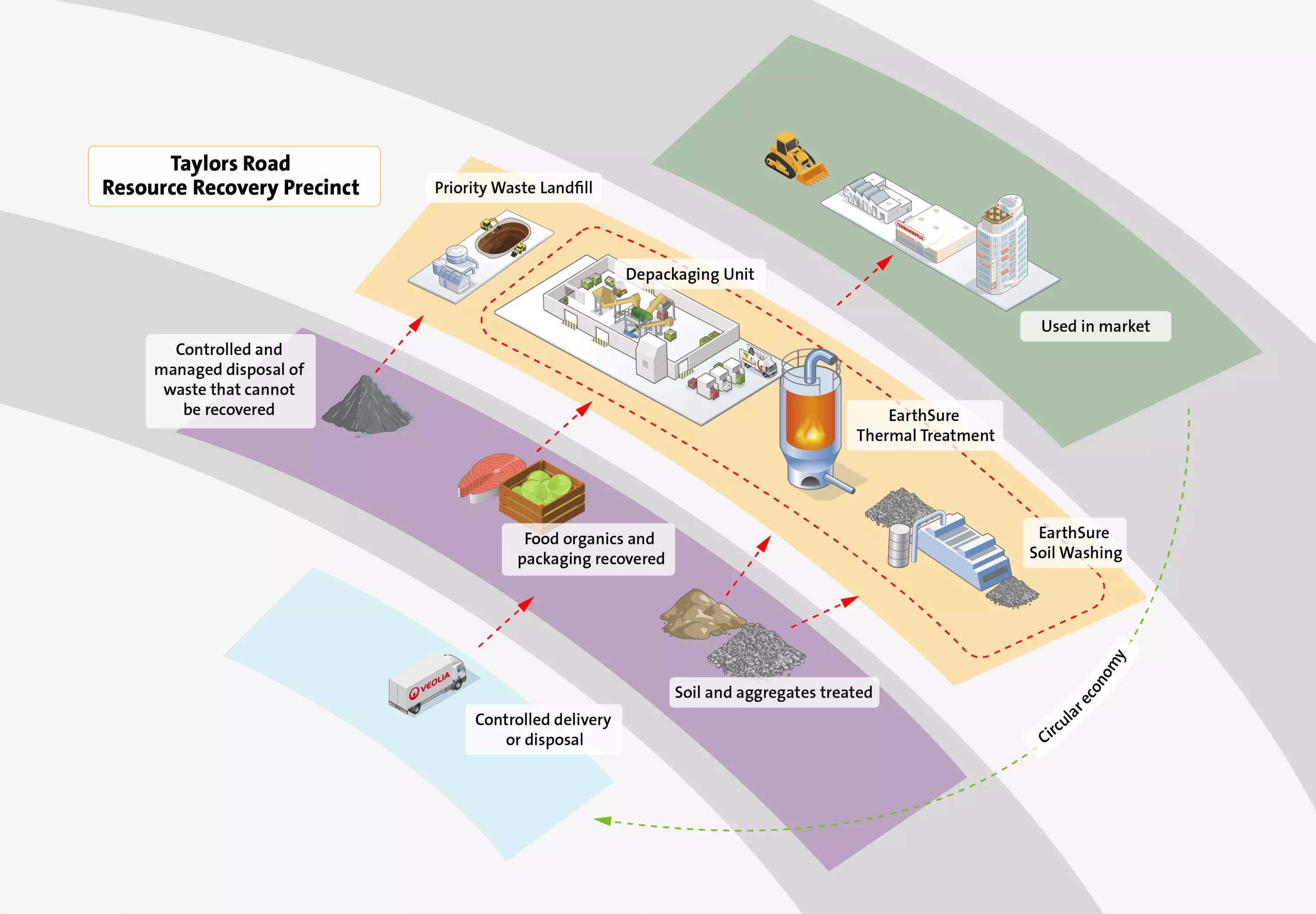

Precinct Overview

Key Site Updates

Addressing Victoria's reportable priority waste needs

The team at Veolia, Taylors Road Landfill would like to make sure you are informed of the proposed development for the final reportable priority waste landfill cell at Taylors Road Landfill.

Veolia’s Taylors Road Landfill has operated as a reportable priority waste landfill at 890 Taylors Road, Dandenong South for over 30 years. The Taylors Road Resource Recovery Precinct has evolved to provide remediation solutions to reduce landfilling and support the circular economy, however being the only landfill of its type in Victoria, it is important to provide a trusted and accessible solution within Australia’s leading manufacturing hub of south east of Melbourne. Continuing operations at this established site which is in proximity to industry, will reduce potential transport constraints. Operationally, approval of the landfill cell would require civil and construction work within the site boundary. The landfill is currently filling a reportable priority waste cell and the development of the new cell would see the continuation of existing landfill management and environmental monitoring practices.

Providing this solution requires an application by Veolia and approval by the Environment Protection Authority (EPA). During this review process the EPA assess a variety of criteria to ensure that the proposal appropriately manages any potential impacts to the health of community and environment.

Posted 21 November, 2024

EarthSure Soil Washing Facility Overview

The EarthSure facility located at the Taylors Road Resource Recovery Precinct (TRRRP) has received funding from Sustainability Victoria's Circular Economy Infrastructure Fund to establish a soil washing facility as EarthSure seeks to treat contaminated soils and recover important resources to support the environment and circular economy.

With planning and Environment Protection Authority approvals achieved, works to establish the facility are underway.

All works including earthworks, connections and commissioning will be completed within the TRRRP site boundary and approved hours. Environmental monitoring and controls including the use of a water cart, street sweeper and a mandatory wheel wash are in place to maintain road conditions.

The project is forecast to be completed in early 2025.

EarthSure Soil Washing Facility Project Update

Significant progress has been made on the construction of the EarthSure Soil Wash Facility (SWF). With civil works and hard stands now completed. Placement and connection of the SWF infrastructure have commenced including the erection of the soil washing plant and closed loop water treatment plant.

The upgraded wheel wash for site wide use is also progressing well. A temporary wheelwash is being operated while the construction of the final automatic high pressure wheel wash system is underway. The permanent wheelwash is due to be operational in early 2025 in preparation for the commissioning of the SWF.

Having reviewed and approved our commissioning plan, site Risk Management and Monitoring Program (RMMP), and Sampling and Quality Plan (SAQP), the EPA have now approved EarthSure the receipt of Category C soil for commissioning purposes. Soil will be accepted and placed on bunded hard stand areas. All environmental and dust management measures are detailed in our RMMP.

CONTACT US

If you would like to get in touch with the engagement team, or provide feedback about key site updates please email [email protected] or call our contact centre on 1800 368 737 and our team will get back to you.

Updated 20 December, 2024

Leachate Pond Works

Why are we undertaking this work?

Veolia will undertake maintenance work for the upkeep of the existing leachate ponds located at the south-east of the site. This work will support the longevity of the leachate ponds used to treat stormwater that has come into contact with waste.

How are we undertaking this work?

Veolia has engaged independent consultants to undertake the design process, risk assessment and delivery of this work.

This work is expected to commence following Environment Protection Authority approval of the proposed works. This communication will be updated once timelines are established.

The leachate within the ponds has been treated and discharged in preparation for the works. This work will be completed on ponds 1,2 and 3. There are an additional 6 ponds on site that can meet the leachate demands of the site.

The pond liner will be removed and disposed of appropriately.

Earthworks will be delivered to replace two existing smaller bund walls with a single, more robust bund wall. The three ponds will become two, however the footprint of the ponds will not change.

With earthworks completed the ponds will be relined and commissioned.

What to expect during this work?

Day to day the facility operates heavy machinery, there are no introduced impacts expected from the delivery of these works. However there may be an increase in traffic for equipment delivery.

The dedicated water-cart will continue to maintain the integrity of the roads and the use of the wheel wash will be enforced.

Posted 10 November 2023

Frequently Asked Questions

Why is this site called Taylors Road Resource Recovery Precinct?

The site has historically been known as Taylors Road Landfill. Since 2017 the site has incorporated new operations to support resource recovery efforts by introducing new waste recycling systems to divert wastes from landfill and recover these wastes for beneficial reuse.

To reflect these solutions the site is now referred to as the Taylors Road Resource Recovery Precinct.

How is Taylors Road landfill licensed?

Located within the City of Dandenong’s Industrial Zone, the Taylors Road landfill has been operating since 1990. Since 2011 the landfill has been licensed to ensure a safe and controlled environment is maintained for the disposal of putrescible and priority waste streams including Category B, and Category C waste.

As a part of this licence, Veolia remains responsible for the restoration of the land and environment during the aftercare period (estimated to be 30 years) from the completion of landfilling, before the land is handed back to the City of Greater Dandenong. The aftercare period is an estimate, as the aftercare will continue until an independent Environmental Auditor and the EPA are satisfied with the site's residual risk.

What type of waste is accepted at the Taylor Road landfill?

The Taylors Road landfill provides responsible environmental management of reportable priority wastes, commonly from businesses and industry.

Waste types accepted:

- Category B and Category C waste including soil - the thresholds for these categories are set and enforced by the Environment Protection Authority under the Environmental Protection Act 2017. Packaged Waste Asbestos - asbestos which is wrapped and contained prior to being transported to the landfill. The site has specific procedures to manage this waste safely.

- Putrescible Waste - This waste category is commonly referred to as household waste, or kerbside waste collected by Councils. It includes material that has a higher organic content that decomposes over time and generates landfill gas. Although licenced for this waste type, the site is currently not receiving putrescible waste

For further understanding of priority wastes details are provided on the EPA website, here.

What are landfill cells?

Engineered landfill cells are constructed to encapsulate waste, leachate and landfill gas within a contained system.

Landfill cells are constructed in accordance with the Environment Protection Authority’s Best Practice Environmental Management, which provides guidelines and legislative objectives. During the construction and capping stages, landfill cells are third party auditor verified and approved by the EPA before filling can commence.

What special controls do priority waste landfills undertake?

The site’s landfill cells are specially engineered in accordance with the EPA’s Best Practice Environmental Management guidelines which specify the quality of materials used to line the landfill cells, provides guidance on landfill gas management, leachate treatment, timely and appropriate waste cover as well as litter controls.

Additional controls include:

- Specialised staff training

- Provision of GPS coordinates for specified waste types

- Immediate cover to receive waste and packaged asbestos

- Administration of the EPA’s waste tracking process for all priority wastes

- Ongoing environmental monitoring

- Third party environmental auditing

What is landfill gas and how is it managed?

Landfill gas is generated within landfill cells as organic matter breaks down over time. However, due to minimal organic material being accepted to site for a sustained period there is a reduced amount of landfill gas being produced.

Landfill gas is managed by placing wells in the waste mass of the landfill cell. The onsite gas capture system draws the landfill gas under vacuum and the combustible methane is flared to reduce emissions and mitigate odour.

What is leachate and how is it managed?

Leachate is liquid generated from the waste mass within the landfill cell, or any liquid that comes in contact with the waste mass.

The design of each landfill cell allows for leachate to be captured and pumped by the leachate sump to the onsite leachate treatment facility.

The leachate treatment facility allows for onsite treatment of the liquid. Treatment includes aeration, which provides an oxygen rich environment for microorganisms to break down ammonia within the liquid. Additional treatments can be applied to restore pH and ammonia balances from time to time.

Following treatment, the liquid meets the environmental standards of the water authority trade waste agreement. An approval is issued by the water authority to discharge liquid to the sewer for further treatment. Each discharge of leachate to the sewer requires a new approval to be issued by the water authority.

Does the site have a Fire Management Plan?

The site has a detailed Emergency Response Plan, which includes responses to fire. This plan details how the site will respond during a fire scenario and demonstrates details such as evacuation procedures, hydrant connection points and specifies water volumes maintained on site. Once Vic Emergency have been notified of an event an evaluation will be made by Vic Emergency regarding the need for community notification.

What happens after the landfill closes?

After the landfill is closed Veolia will remediate and maintain the site during the aftercare period (which is estimated to be 30 years). The land will be returned to the council after remediation has been achieved and it has been approved as compliant by an independent auditor and EPA.

The operation of EarthSure is contingent on the landfill being operational.

During the aftercare period Veolia will be responsible for:

- Capping the final landfill cell and remediation of landscape

- Ongoing environmental monitoring of landfill gas, leachate, groundwater and stormwater

- Ongoing maintenance of the site including landscaping and the landfill infrastructure that manages leachate and the landfill gas network

- Ongoing engagement of a landfill gas management contractor who converts landfill gas into electricity.

You can learn more about the management of closed landfills via the EPA’s resources here

What other treatment options are available at the site?

Ecological transformation is Veolia’s purpose. The Taylors Road site accepts priority wastes as a disposal option and is invested in providing further treatment options through its joint venture EarthSure which processes soil to remove contaminants allowing beneficial reuse.

To explore our disposal and treatment options for a wide variety of impacted materials click here.

What is the depacking facility and how does it work?

The depackaging facility has been designed to use a mechanical mechanism to separate food waste and recycling into two separate waste streams. The recovered materials are collected in sealed containers and processed at specialised food organics, garden organics recycling facilities.

To manage odour associated with organic material:

- The facility has high velocity fans to turn over the air within the enclosed facility. In addition to this the facility has rapid shutter doors to support the effectiveness of the high velocity fans.

- Organic material is containerised in sealed vessels and taken off site daily

What is EarthSure?

Located at the Taylors Road Landfill site, in Victoria, EarthSure, a joint venture between Veolia and Ventia is a lawful premise licensed by the EPA if Victoria to receive and treat Category C, B and A soils and wastes by thermal treatment and stabilisation.

How are contaminants removed?

Contaminated waste delivered to the facility is unloaded in a fully enclosed Pretreatment Building (PTB) where the waste is pretreated including homogenisation, drying, screening and crushing as required. The PTB is serviced by an Emissions Control System (ECS) which extracts the air in the PTB and purifies it through a series of particulate and activated carbon filtration. A PID ( Photoionisation Detector) continuously monitors quality of the purified air released from the ECS emissions stack.

Pretreated contaminated soil is fed into our thermal treatment plant where it is heated in a Primary Treatment Unit (PTU) to drive off the organic contaminants from the soil, rendering the soil clean. The organic contaminants are routed into a Secondary Treatment Unit (STU) where they are destroyed to form simple molecules such as water, carbon dioxide, and salt (NaCl).

The treated soil discharged from our thermal treatment plant is quarantined, analysed, and repurposed for recycling on a range of beneficial reuse.

What happens to the processed material?

Clean soil is returned to the source site or reused elsewhere as engineering fill. In the absence of demand, treated and stabilised soils are sent to the Taylors Road landfill, where they are used as landfill buffer/bedding sand or as daily cover in place of clean fill that would otherwise have to be imported for these purposes.

What is Thermally Treated Material (TTM)?

Thermally Treated Material is soil that has received processing using thermal desorption as offered by EarthSure.

Through the heating process organic contaminants are removed and destroyed.The thermally treated material is quarantined and analytically tested by independent NATA registered laboratories before is it removed from the EarthSure facility for beneficial reuse.

What is the soil wash plant and how does it work?

EarthSure’s soil wash plant provides a closed loop system by treating and removing contaminants from the environment. The recovered resource is then returned to market as construction aggregate to reduce the demand for raw materials.

This facility is currently being established and is expected to be available to support the environment and the market in early 2025.

What is the temporary storage area and how does it work?

Category A, B and C materials are currently accepted into EarthSure’s treatment facility.

To support spikes in demand for recycling of Category C soils and expedite their removal from construction sites, the temporary storage area has been established. Category A, B materials are not stored in this temporary storage area.

The soil stored in this temporary storage area will be managed utilising a combination of sprinkler systems, materials handling procedures and fencing for wind breaks.

What hours does the EarthSure facility operate?

Materials can be accepted to the EarthSure facility via the Taylors Road weighbridge, operational Monday - Friday 7am - 3pm, or via confirmed arrangement.

The EarthSure facility is licenced to operate 24/7. Operation of the facility is planned to ensure efficient processing of material.

What environmental controls are in place?

The thermal plant is computer controlled. There are a total of 500 input and output control and measurement points that are constantly monitored on the plant to ensure its safe operation. A Continuous Emissions Control System (CEMS) continuously samples and measures the quality of the thermal plant’s stack emission to ensure compliance with our EPA licence. The CEMS is also interlocked to automatically stop feed to the plant to ensure our licence limits are not exceeded.

How is air monitoring undertaken?

Priority Waste Landfill Air Monitoring:

The site operates under an Operations Licence issued by the Environment Protection Authority (EPA) which is the regulator's mechanism for imposing strict conditions to prevent and manage any potential harm to the environment and human health regarding the landfill's operations.

In 2021 an EPA-appointed auditor recommended that the ‘air toxics’ monitoring program could be discontinued due to consistent non detections of toxics in local ambient air samples. Despite the low risk the site has taken a conservative approach since the recommendations of the 2021 EPA-appointed Environmental Audit and has undertaken periodic local air quality monitoring.

Air quality monitoring of the active landfill cell includes volatile organic compounds, metals, asbestos, Particulate Matter 10 micrometers or less in diameter (PM10) and Particulate Matter 2.5 micrometers or less in diameter (PM2.5).

EarthSure Thermal Facility Monitoring:

The facility operates under its own Operating Licence issued by the Environment Protection Authority (EPA), which includes strict environmental guidelines for air emissions.

The thermal facility is controlled by a computerised system and is equipped with a Continuous Emissions Monitoring System (CEMS) to ensure compliance with EPA regulations at all times.

Additionally continuous dust monitoring is undertaken at the boundaries of the thermal and soil washing facilities.

Taylors Road Resource Recovery Precinct Community Reference Group (CRG)

The Group provides a forum for discussion and feedback between the Veolia project team and representatives of the community and local councils on matters relating to the Taylors Road facility. This facilitates community awareness of the operations, environmental performance and any development of the facility, and fosters understanding and cooperation to minimise the impact of the facility on the local community. The CRG is not a decision-making body; it performs an advisory and consultative role.

If you are interested in knowing more, please contact Currie for a copy of the Terms of Reference and nomination form:

- Email [email protected]

- Call 0439 389 202

Taylors Road CRG Meeting Minutes

2025

2025 March: Taylors Road CRG Meeting Minutes

2025 May: Taylors Road CRG Meeting Minutes

2025 August: Taylors Road CRG Meeting Minutes

2025 December: Hampton Park and Taylors Road Combined CRG Meeting Minutes

2024

2024 March: Taylors Road CRG Meeting Minutes

2024 June: Taylors Road CRG Meeting Minutes

2024 September: Taylors Road CRG Meeting Minutes

2024 December: Hampton Park and Taylors Road Combined CRG Meeting Minutes

2023

2023 March: Taylors Road CRG Meeting Minutes

2023 June: Taylors Road CRG Meeting Minutes

2023 October: Taylors Road CRG Meeting Minutes

2023 December: Hampton Park and Taylors Road Combined CRG Meeting Minutes

2022

2022 October: Taylors Road CRG Meeting Minutes

2022 December: Hampton Park & Taylors Road CRG Meeting Minutes

CONTACT US

If you would like to get in touch with the engagement team, or provide feedback about key site updates please email [email protected] or call our 24/7 contact centre on 1800 368 737 and our team will get back to you