The Veolia organic waste facility, located in Bulla, 30km North of Melbourne, will use state-of-the-art Australian-made technology to turn thousands of tonnes of organic waste into high-grade composts and mulches.

The Bulla organic waste facility processes 85,000 tonnes of green organics, lawn clippings, garden waste and food scraps annually. The highly efficient facility will convert the otherwise landfill-bound waste into approximately 60,000 tonnes of high-grade composts (40,000T) and mulches (20,000T), which will, in turn, be sold to local garden centres (soil production and landscape companies), civil construction, horticulture, viticulture and our largest network of broad acre farmers producing our everyday food needs. The end product aims to increase the carbon within the soil to ultimately improve soil health.

The facility receives, processes and repurposes organic waste delivered by the Department of Energy, Environment and Climate Action (DEECA) and 11 participating councils in the north and west of Melbourne. The facility is currently contracted to handle the organic waste processing for the region until 2027 and expects to continue its work returning organic material to the environment well into the foreseeable future.

Capacity to process 85,000 tonnes per year

Accepting waste from 11 Melbourne region councils

Produces up to 60,000 tonnes of high-grade compost annually

About the process

Bulla Organics in-vessel composting system provides an efficient and environmentally conscious way of recycling food scraps and other organic waste. The facility uses 14 enclosed vessels to create the ideal conditions for pasteurisation and decomposition of the organic material.

Following initial screening and shredding, through carefully controlled aeration, moisture levels, and temperatures reaching 55°C or higher, pathogens are eliminated from the waste stream. The high heat pasteurises the material, allowing beneficial microbes to then break it down into a nutrient-rich compost product.

This soil conditioner can be used by farmers, landscapers, and home gardeners as a soil amendment, returning valuable nutrients to the earth in a sustainable cycle. In-vessel composting is a win-win, diverting organic waste from landfills while creating a useful agricultural product.

Supporting the Circular Economy

What does the site accept?

- Branches, twigs & leaves

- Lawn clippings & weeds

- Fruit & vegetable scraps

- Meat & bones

- Citrus, onions & garlic

- Seafood

- Dairy products & egg shells

- Bread, pasta & rice

- Coffee grounds & loose leaf tea

- Newspaper sheets (as wrapping / lining for Food only)

- Paper towels (as wrapping / lining for Food only)

- Paper caddy liners (as wrapping / lining for Food only)

Rough rule of thumb for what can go into a FOGO bin is anything that grows in your garden or you can eat.

What the site does not accept?

- Plastic Bags / Packaging of any variety (including certified compostable bags)

- Cigarette Butts

- Nappies / Baby wipes

- Paper (office paper / tissues) (Large volume paper towel / newspaper)

- Chemicals / Batteries

- Coffee Pods

- Tea Bags

- Coffee Cups (all kinds)

- Kitty Litter (all kinds)

- Animal Droppings

- Ash / Tree Stumps

- Glass / Metal

- Cateringware plastic / wood - bamboo

A great resource is the Household Waste and Recycling Service standard 2024 from Recycling Victoria for a more in depth listing.

Standard contents list for FOGO service

How is the FOGO screened?

Once the organic material is delivered, it is mechanically agitated and sorted in the early stages to remove contaminants, it is then visually assessed and manually picked by our dedicated picking team to remove unwanted items like plastics and garden tools.

How is the FOGO pasteurised?

Screened material is shredded and placed in large vats where air is pumped through to encourage microbial bugs to break down the organics. The introduced air stimulates the bugs, encouraging them to break down the material. Their activity generates heat during this process. After an average of 5-7 days we can monitor and guarantee that we have pasteurised the material to meet Australian Standard 4454. This process is referred to as in vessel composting which uses aeration. During this process the organics are turned into nutrient rich compost which can be used by farmers and in other land use.

Is the finished soil conditioner safe for growing food crops?

Yes, the high-heat pasteurisation process eliminates pathogens and destroys weed seeds and other contaminants. The finished soil conditioner meets strict regulatory standards for safely amending agricultural soils used for growing food crops.

How long does the full composting process take?

What would usually take two months in a wind row, requiring management and turning we achieve in 5-7 days using the in-vessel system. We ensure that we achieve 76 hours of temperatures over 55 degrees celsius at a minimum. The Australian Standard is 72 hours to consider the product pasteurised.

Does the site accept plastic or compostable bags?

The site does not accept any type of plastic or compostable bags due to the potential safety and contamination risks they pose. Yes, this includes compostable bags as during the screening process plastic and compostable bags cannot be distinguished apart. They all have to be assumed to be plastic due to the contamination risk. The screened and separated items are disposed of appropriately. From a safety point of view, we can not see within the bags so they are also removed to reduce our risks to staff or the soil conditioner product.

Why can’t we use compostable bags?

The work overseas is still ongoing though apart from the soil & chemical analysis etc there are a couple of other stand out issues with using compostable bags which I hope may address any questions you may receive:

- Some people place contamination inside the bag. In theory, if we would let a compostable bag go through our sorting process and if there is a plastic wrapper, glass bottle, (or worse) piece of asbestos or a syringe in that bag it would go through to our end product instead of being identified during the decontamination process. Manually breaking these bags open presents an additional Safety risk to workers exposing them to the aforementioned hazards.

- There is no standard as to what a compostable bag must look like, making them difficult to identify during our sorting process. Our sorters do roughly 1 pick per second. This is a very short amount of time to identify whether a bag is certified compostable or not.

- If a knot is tied in the bag, the knot will take an exceedingly long time to break down (we have seen these take in excess of a year). Remnants of compostable bags are counted towards the maximum 0.05% contamination in our end product which is governed by Victorian EPA.

Can shells from seafood (e.g. mussels) be put into the green waste bin?

Yes. Shells soften and crumble when agitated during the composting process. They also add valuable calcium to the compost.

Can wood shavings and sawdust be put into the green waste bin?

Generally no. As a lot of timber used in construction has been treated in some way (ie. Treated Pine) this introduces chemical contamination to our compost. There is no way for us to tell if the dust/shavings are treated or not as they aren’t identifiable.

Can coffee husks be put into the green waste bin?

Yes. Coffee husks and grounds can go in the green waste bin for composting.

Can animal faeces or kitty litter be put into the green waste bin?

No. Faeces cannot be placed into the green waste bin.

Why don’t you accept tea bags?

The main issue with tea bags is the small tag that hangs off the side. This is quite often a coated material or a thick cardboard that doesn't break down in the vessel process. This then leaves us with colourful little labels that stand out in our compost. The small staple that attaches the string is so small that it also goes through into our end product. As with compostable bags, as there is no clear way to identify a compostable tea bag, these are not accepted.

Do we accept shredded paper?

No we don’t. Paper can be of varying grades and breaks down at varying speeds, or it may be coated. The best place for paper is your recycling bin.

Paper towel/newspaper (small amounts)?

When it comes to paper towel and newspaper we allow 1 or 2 sheets that has been used to wrap/transport food. The one to avoid is people using bulk amounts of paper towel and placing it in the bin.

Cooking oil?

How much of this would be placed in the bin? Liquids should generally not be placed into any bin so this should be avoided. Oils work fine in the composting process (and we do receive it from alternative sources at our facilities) though this would be more about how the material is placed in the bin.

Paper bags (if non waxed, eg. mushroom bags)?

See above for what is allowed on the paper front. Paper is better suited in the recycling stream. There are varying grades of paper all of which break down at varying rates so at this stage they aren't accepted. Some paper bags as caddy liners are fine so long as they aren’t waxed/coated/treated in any way.

Vacuum dust?

The main concern with vacuum dust is potential small contamination that is also vacuumed up.

Hair / Animal hair?

Yes only if its not dyed or synthetic hair as it can contain a lot of chemicals that can affect our organic certification.

Soil?

Small amounts on the roots of plants/weeds causes no issues. Larger amounts, no. Soil will not break down any further and is very dense (preventing airflow through our composting vessels). The best place for soil is back in the garden!

Dog and cat food – pet food?

We've never seen an animal leave much food behind, although this is fine in a FOGO bin.

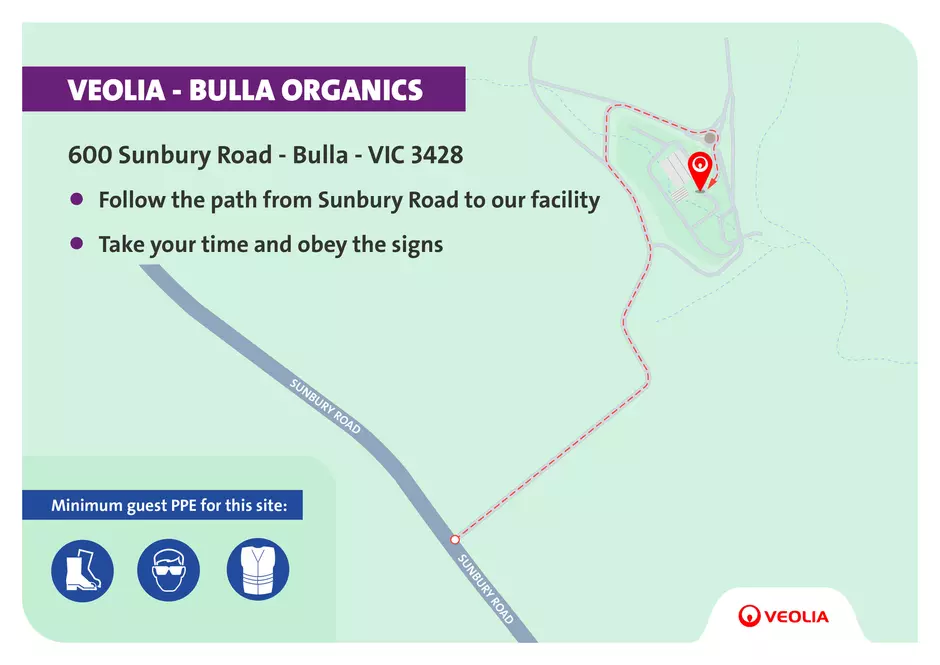

-Getting to Bulla Organics Facility-

CONTACT US

If you would like to get in touch with the engagement team call our contact centre on 1800 368 737 and our team will get back to you