BALLARAT NORTH PLANT

Water reclamation, treatment & reuse plant

| The Challenge

Central Highlands Water is a regional water corporation providing high quality drinking water, sewerage, trade waste and recycled water services to customers in Ballarat and surrounding towns.

In 2005, Central Highlands Water issued a brief to industry for its Ballarat North Water Reclamation Project with the objective of constructing a new treatment plant to increase the wastewater treatment capacity to the region.

| Veolia’s Solution

Providing additional wastewater treatment

- This contract commenced in 2006 and initially involved Veolia taking over the operations of an existing wastewater treatment plant.

- In 2007, construction commenced on the new Ballarat North Water Reclamation Plant. Veolia are now operating the plant under a 15 year contract.

- This plant was completed in 2008 and is capable of treating 8.4 megalitres of wastewater per day while improving the quality of treated water discharged to the environment. It also includes a thermal sludge dryer which produces biosolids to a standard suitable for blending with green-waste compost for beneficial reuse.

- The plant capacity was upgraded to 10.6MLD in 2023 to meet the growing needs of the community.

- In 2009, Veolia also took responsibility for the operations and maintenance of another new plant, the Ballarat North Reuse Plant. This facility treats effluent from the Ballarat North Water Reclamation Plant and capable of producing 5 MLD Class A water.

- This recycled water is available for a variety of uses including distribution into Lake Wendouree, the major recreational lake in Ballarat.

Production of biosolids for reuse

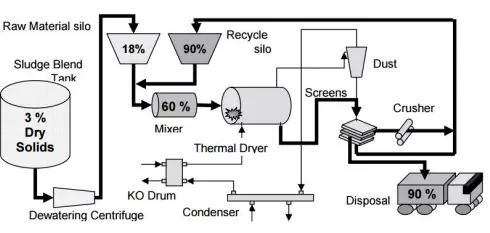

Centrifuge – Sludge is recovered from the wastewater treatment process in a blend tank which creates a consistent mix for dewatering. Dewatering occurs as required with two centrifuges and then transferred to a thermal dryer.

Mixing - The sludge mixing process consists of mixing the dewatered sludge with dried recycled product before feeding into dryer.

Thermal Drying - The biosolid mix is then moved into a thermal dryer, which is a gas fired burner rotary drum system operating at up to 550 degree C to ensure pathogen kill, ending up producing a > 90% dry granule biosolids product.

Screening - The product then is mechanically sized in a series of screens for consistency. Once screened, the product is then suitable for reuse, meeting the stringent EPA biosolids guidelines requirements.

Like this solution?

Start implementing proven tactics today!

Explore our range of services to discover how you can achieve your operational and sustainability goals.

| The Benefits

- The plant increases the treatment capacity while reducing the pollution load before discharging the final treated effluent back into receiving waters which is the Burrumbeet Creek that flows into Lake Burrumbeet.

- Up to 5 MLD water produced for reuse.

- Biosolids from the new plant are transported offsite to a composting facility located on the western fringe of Melbourne.

Veolia have been a valuable partner to CHW for decades. Together we have provided outstanding outcomes to our customers and community. Paul Donohue, General Manager, Infrastructure Planning & Operation, Central Highlands Water

HOW CAN WE HELP?

Our team of industry experts are here to support you and your business. We work alongside you to propel your sustainability efforts forward and achieve a common goal of Ecological Transformation.